5:1 Design for use with powered or manual hoists – 1/2 ton to 5 ton WLL

* including Wide Flange Kit

| Model | WLL (5:1) | A (in) | B (in) | B2* | Standard C (in) | Wide Flg Kit C2 (in)* | D (in) | E (in) | F (in) | G (in) | H (in) | I (in) | J (in) | K (in) | L (in) | M (in) | P (lbs) | R min (in) | W1 (lbs) | W2 (lbs)* | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PT005 | 1/2t | 3.3 | 11.5 | 14.8 | 1.97-8.66 | 6.30-12.01 | 0-0.12 | 1.5 | 2.3 | 3.4 | 1.2 | 0.9 | 8.9 | 6.8 | — | 4 | — | 36 | 18 | 19 | |

| PT010 | 1t | 3.7 | 11.8 | 15.2 | 2.28-8.66 | 6.30-12.01 | 0-0.12 | 1.7 | 2.4 | 3.7 | 1.4 | 0.9 | 9.9 | 7.4 | — | 4.8 | — | 40 | 24 | 25 | |

| GT010-20 | 1t | 3.7 | 11.8 | 15.2 | 2.28-8.66 | 6.30-12.01 | 0-0.12 | 1.7 | 2.4 | 3.7 | 1.4 | 0.9 | 9.9 | 7.4 | 4.5 | 4.8 | 18 | 40 | 35 | 36 | |

| PT020 | 2t | 4.4 | 12.2 | 15.6 | 2.60-8.66 | 6.30-12.01 | 0-0.12 | 1.6 | 3.2 | 4.6 | 1.9 | 1.0 | 11.8 | 8.9 | — | 5.5 | — | 48 | 40 | 42 | |

| GT020-20 | 2t | 4.4 | 12.2 | 15.6 | 2.60-8.66 | 6.30-12.01 | 0-0.12 | 1.6 | 3.2 | 4.6 | 1.9 | 1.0 | 11.8 | 8.9 | 4.5 | 5.5 | 34 | 48 | 51 | 53 | |

| PT030 | 3t | 5.8 | 12.8 | 16.1 | 2.91-8.66 | 6.30-12.01 | 0-0.12 | 2.5 | 3.9 | 5.5 | 2.3 | 1.3 | 14.2 | 11.4 | — | 6.3 | — | 52 | 69 | 72 | |

| GT030-20 | 3t | 5.8 | 12.8 | 16.1 | 2.91-8.66 | 6.30-12.01 | 0-0.12 | 2.5 | 3.9 | 5.5 | 2.3 | 1.3 | 14.2 | 11.4 | 5.3 | 6.3 | 27 | 52 | 83 | 85 | |

| PT050 | 5t | 6.3 | 13.0 | 16.3 | 3.54-8.66 | 6.30-12.01 | 0-0.12 | 2.2 | 4.3 | 5.9 | 2.8 | 1.5 | 15.4 | 12.3 | — | 6.7 | — | 56 | 94 | 97 | |

| GT050-20 | 5t | 6.3 | 13.0 | 16.3 | 3.54-8.66 | 6.30-12.01 | 0-0.12 | 2.2 | 4.3 | 5.9 | 2.8 | 1.5 | 15.4 | 12.3 | 5.4 | 6.7 | 36 | 56 | 108 | 111 |

4:1 Design for use with manual hoists. For powered hoists reduce WLL by 20% – 10 ton to 30 ton WLL

| Model | WLL (4:1) | A (in) | B (in) | C (in) | D (in) | E (in) | F (in) | G (in) | H (in) | I (in) | J (in) | K (in) | L (in) | M (in) | P (lbs) | R min (in) | W (lbs) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PT100 | 10t | 7.5 | 15.5 | 4.9-12.0 | 0.08-0.13 | 1.8 | 7 | 5.4 | 4.4 | 2.8 | 18.1 | 15.5 | 1.8 | 7.9 | — | 79 | 198 | |

| GT100-20 | 10t | 7.5 | 15.5 | 4.9-12.0 | 0.08-0.13 | 1.8 | 7 | 5.4 | 4.4 | 2.8 | 18.1 | 15.5 | 4.3 | 7.9 | 54 | 79 | 207 | |

| PT160 | 16t | 9.3 | 17.1 | 5.4-12.0 | 0.08-0.13 | 2.4 | 8.9 | 6.6 | 5.4 | 3.7 | 22.6 | 19.6 | 3 | 10.7 | — | 138 | 427 | |

| GT160-20 | 16t | 9.3 | 17.1 | 5.4-12.0 | 0.08-0.13 | 2.4 | 8.9 | 6.6 | 5.4 | 3.7 | 22.6 | 19.6 | 6.0 | 10.7 | 54 | 138 | 447 | |

| GT200-20 | 20t | 9.2 | 17.1 | 5.4-12.0 | 0.08-0.13 | 2.3 | 8.9 | 6.9 | 5.4 | 3.7 | 22.6 | 19.6 | 6.0 | 10.7 | 56 | 138 | 458 | |

| GT300-20 | 30t | 11.2 | 17.8 | 6.9-12.0 | 0.08-0.13 | 2.7 | 11.2 | 9.1 | 6.1 | 4.1 | 28.7 | 24.4 | 6.2 | 13.5 | 56 | 236 | 848 |

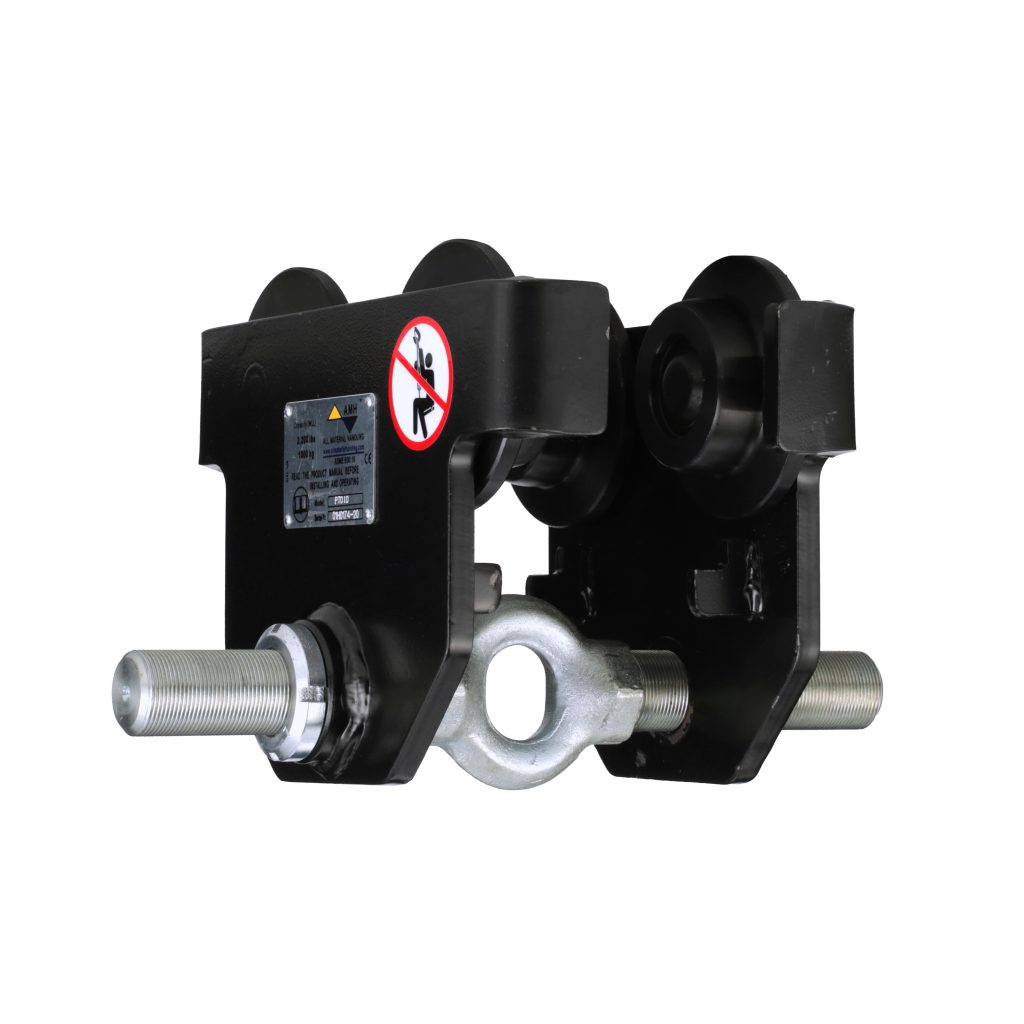

- 1/2 to 30 Metric ton capacity

- The easiest trolley installation ever

- ½ to 5t installation and adjustment by rotating the threaded hanger shaft.

- 10-30t installation from one side. Hanger shafts are fixed mounted to the opposite side plate.

- Trolleys up to 5t have a 5:1 design factor for use with powered or manual hoist. Trolleys 10t and greater have a 4:1 design factor and must be derated for use with powered hoist.

- Machined cast iron wheels with universal tread designed to fit flat or tapered beam flanges.

- Low headroom design with precision sealed “lubed for life” bearings assure smooth operation.

- Durable all steel construction with standard safety lugs

- Geared trolley hand chain comes standard with 20 feet of drop

- Meets: ASME/ANSl B30.16, OSHA, NASA-STD-8719.9, EU Directives: 2006/42/EC

- ATEX rated

certified II 3 GD c IIB 54º C X for limited use in Hazardous Environments

certified II 3 GD c IIB 54º C X for limited use in Hazardous Environments

Options

- Extended hand chain drop (standard with 20 ft)

- Wide Flange Kits for ½-5t with 12″ flange adjustment (may be ordered separately)